WhatsNew Category: "Cement"

January 06, 2021 Cement

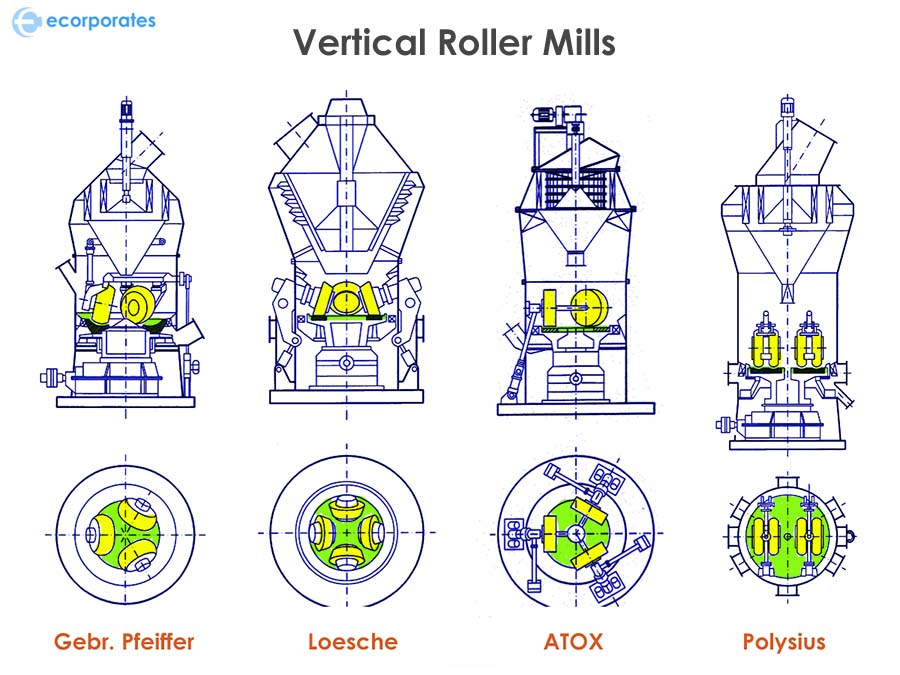

Vertical Roller Mill for Grinding in Cement Industry

Our team of experts recently performed audit of a vertical grinding mill and supplied new wear segments of table and roller tires along with commissioning supervision. The parts were supplied in high chromium which can be later rebuilt and hard-faced. The customer also ordered new rotary valve which reduces false air entering with feed material.

Vertical Mills perform grinding, drying and separation of solid material in single operation.

The vertical mills can be divided into three major sections i.e., Drive, Grinding and Separation. The material falls on grinding table to form material bed. The table moves with drive and roller tires rolls freely which perform grinding of material.

Grinding force = Roller weight + Force

Grinding force = Roller weight + Force

The maximum particle size in feed is about 5-8% of roller diameter

The hot air is blown under the table which moves the grinded material to separator. The separator removes fine material and reject coarse material. The large material falls through scraper.

Major vertical mill being used in cement industry are from following manufacturers

• FLSmidth

• Loesche Mill

• Polysius Mill

• Gebr Pfeiffer

Ecorporates © 2025. All Rights Reserved